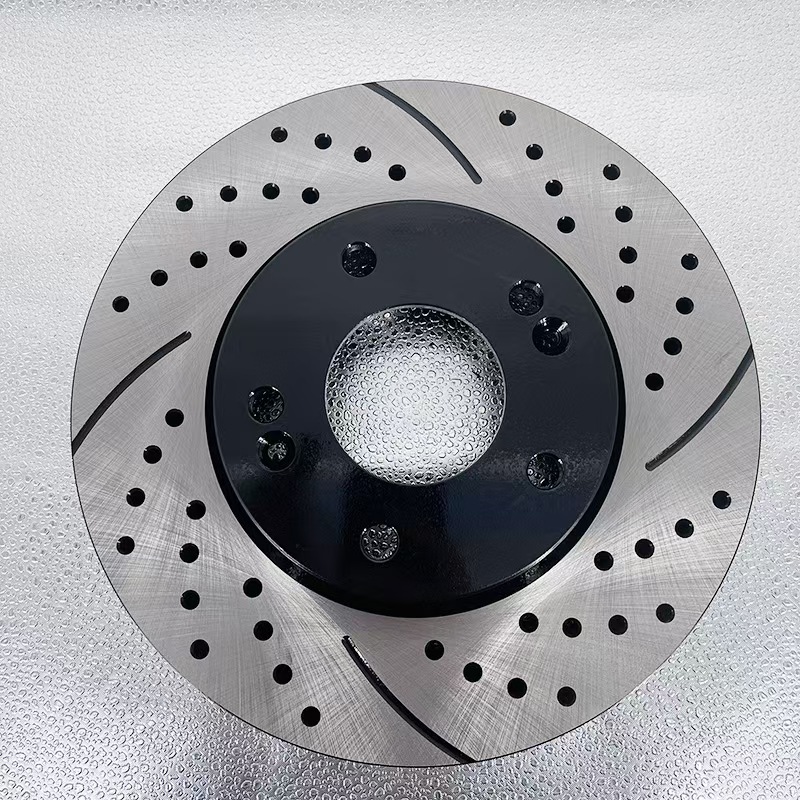

Drilled and Slotted Brake Disc Genuine HT250/G3000 Brake Disc High Quality Materials 8J0615301 for Audi Vehicles

Genuine HT250/G3000 Brake Disc High Quality Materials 8J0615301 for Audi Vehicles

$60.00

AUDI BRAKE DISC

Grey Cast-Iron G3000 – cast, precision-machined and balanced to Audi OE standards for factory fit, sport-level heat capacity and quattro-riveted confidence.

Manufactured in an IATF-16949 facility that also feeds VW Group assembly lines.

1. 100 % AUDI OE GEOMETRY

– CNC-turned outer Ø, thickness, bolt circle and hat height to Audi blueprint—installs without spacers, shims or coding.

– Hub register and ABS tone-ring teeth held ± 0.01 mm—zero run-out, no brake judder or ESC faults.

2. GREY CAST-IRON G3000 COMPOSITION

– 3.3 % C, 2.0 % Si, 0.7 % Mn, ≤ 0.15 % P, ≤ 0.12 % S—identical chemistry used on A3, A4, Q5, Q7 production.

– Pearlite matrix, 200-230 HB: high wear resistance, excellent thermal conductivity and natural damping for Audi-class NVH.

3. HIGH-PERFORMANCE VENTILATED CORE

– 60 directional “pillar” or curved vanes increase airflow 20 %, cutting peak temperature 80 °C during repeated 250-80 km/h Autobahn stops.

– Single-piece casting—no welded seams to fail under S/RS track-day thermal cycles.

4. SURFACE FINISH & PRECISION BALANCE

– Non-directional swirl, Ra ≤ 1.6 µm—beds-in within 20 stops, no greenfade.

– Dynamic balanced ≤ 0.8 g—steering-wheel shake free at Audi’s 250 km/h (155 mph) limit.

5. ANTI-CORROSION COATING

– Full-surface Geomet® or electro-zinc layer—144 h salt-spray per ASTM B117, survives Alpine winters and coastal humidity.

– Friction faces uncoated for immediate use; protective oil film burns off on first brake application.

6. QUIET, LOW-DUST DESIGN

– Precision dual-radius chamfers plus 0.30 mm under-cut slots prevent pad-knock and squeal.

– Optimised for Audi low-met and ceramic formulations—low dust, no black rims on S-design alloy wheels.

7. VALIDATION TESTS

– 500-cycle AK-Master (250-80 km/h, 5 kW power) wear ≤ 0.30 mm—within Audi 0.5 mm limit.

– Thermal shock: 600 °C → 20 °C water quench, 50 cycles—no surface cracks, distortion < 0.03 mm.

8. SERVICE LIFE & FITMENT

– 80 000–100 000 km normal street use; 40 000 km severe duty (taxi, police, Alpine passes).

– Direct replacement for selected Audi models—see reverse for PR-code / VIN list.

– Replace in axle pairs and use Audi-specified pads for optimum pedal feel and ESC compatibility.

INSTALLATION NOTE

Clean hub face with wire brush, apply thin anti-seize on contact shoulders only, torque wheel bolts to 140 N·m (M14) in star pattern.

Bed-in: 8 moderate stops 100 km/h → 30 km/h with 30 s cooling between each.

TYPICAL FRONT DISC SPEC (18″ wheel, B9 A4)

Outer Ø: 338 mm

Thickness new: 34 mm

Min. thickness: 32 mm

Centre bore: 68.1 mm

Bolt pattern: 5×112 mm

Weight: 8.8 kg

Material: G3000 grey cast iron, heat-treated

Max run-out: 0.025 mm

Thickness variation: ≤ 0.010 mm

Restore the precise, confident braking quattro engineers designed—choose Audi Genuine Technology brake discs.